When it comes to trailer manufacturing and refurbishment in Newcastle and the Hunter, the finish you choose can have a long-term impact on durability, aesthetics, and cost. Two common methods are traditional wet painting and powder coating. But which is best for trailers?

What Is Powder Coating?

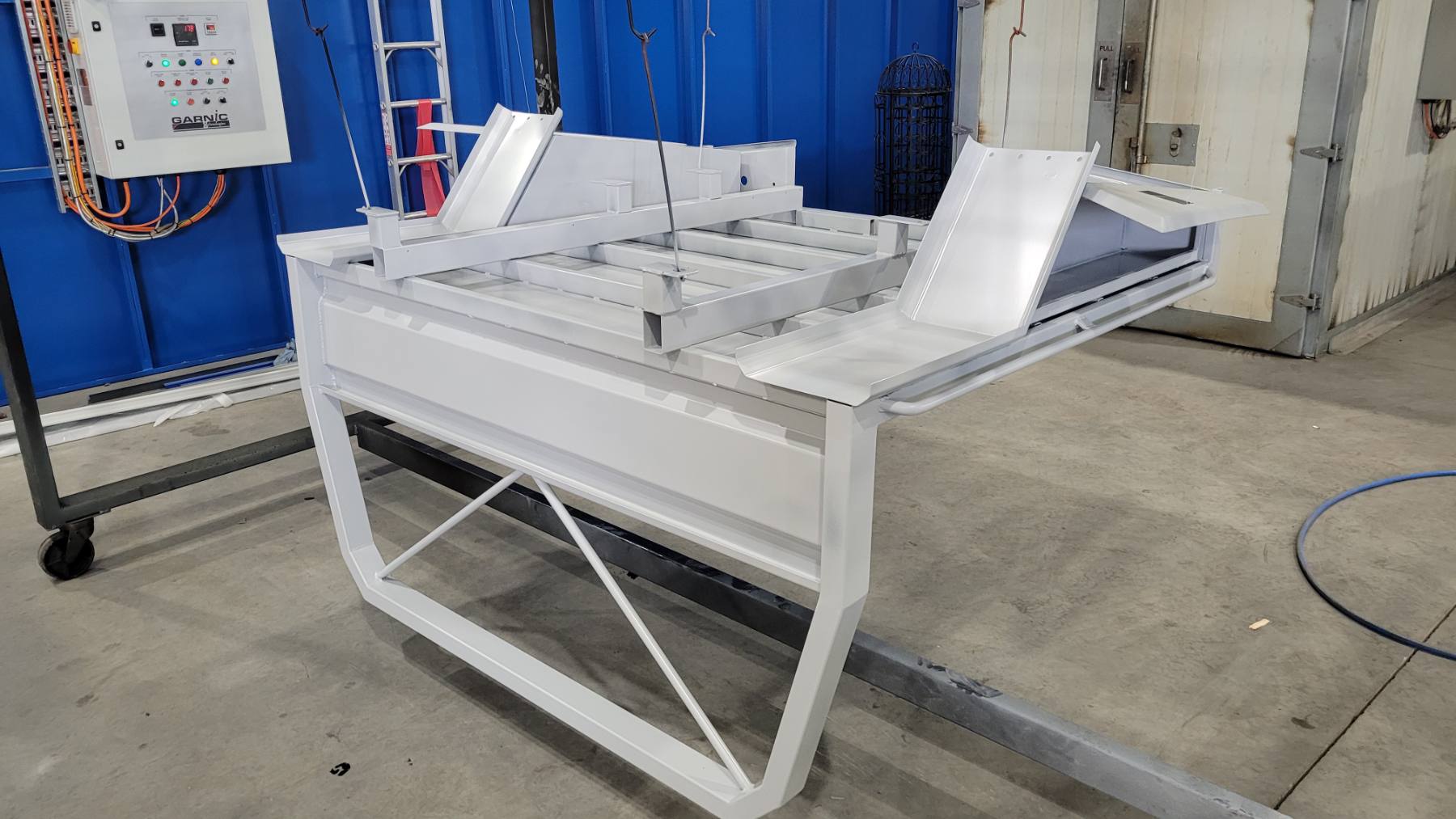

Powder coating is a dry finishing process that involves electrostatically applying a powder to a metal surface, then curing it under heat to form a protective layer. It’s known for its toughness and resilience.

What Is Traditional Wet Paint?

Traditional paint involves liquid application, typically via spraying, and relies on solvents and air-drying or low-heat baking. It’s the older, more familiar method in trailer manufacturing.

Durability: Which Finish Lasts Longer on Trailers?

Powder coating offers superior durability. It’s resistant to chips, scratches, and UV damage—ideal for trailers exposed to Newcastle’s coastal climate. Traditional paint, while adequate, tends to wear more quickly, especially under heavy use or in harsh weather.

Corrosion Resistance: Protecting Trailers in Newcastle’s Coastal Conditions

Powder coating forms a thick, consistent barrier that shields trailers from moisture and corrosive salts. This makes it highly suitable for trailers used in or near Newcastle’s marine environments. Paint, depending on quality and application, may not offer the same level of protection.

Environmental Impact: Which Is More Sustainable?

Powder coating is the eco-friendlier option. It contains no solvents, releases negligible VOCs (Volatile Organic Compounds), and overspray can be reclaimed. Traditional paint contains VOCs and generates more hazardous waste.

Cost Comparison: Initial Investment vs Long-Term Value

While powder coating may have a higher upfront cost, it offers better long-term value due to lower maintenance and longer life. Paint is cheaper initially but may require more frequent touch-ups and repainting.

Aesthetic Finish: Which Looks Better on a Trailer?

Powder coating provides a smooth, even, and often glossier finish. It also comes in a wider range of textures and colours, maintaining its appearance longer. Traditional paint may suffer from runs, drips, or fading over time.

Application Time: Which Is Faster for Trailer Manufacturers?

Powder coating involves quicker curing times and fewer steps, especially with automated systems. Paint requires longer drying periods and multiple coats, which can delay turnaround times.

Adhesion and Surface Preparation

Both methods require surface preparation, but powder coating requires a clean, often sandblasted surface to ensure adhesion. Traditional paint may adhere to a wider range of surfaces but won’t perform as well if the prep is rushed.

Which Finish Is Best for Newcastle Trailer Owners?

For Newcastle-based trailer manufacturers and users, powder coating provides better protection, durability, and sustainability, especially in coastal and industrial environments.

Final Verdict: Powder Coating Wins for Long-Term Value

While traditional paint still has its place for quick touch-ups or low-cost projects, powder coating stands out as the superior choice for trailers in Newcastle looking for a long-lasting, weather-resistant, and visually appealing finish.

If you’re looking for reliable powder coating services in Newcastle, consider a provider experienced in trailer applications to maximise performance and value.

For more information or a quote on powder coating your trailer in Newcastle or the Hunter Valley, contact your local experts today.

Powder Coating Industries Phone: (02) 4052 9022