Need something powder coated?

Call us for expert advice on powder coating your metal items.

PHONE: 0240529022

We are known for high quality powder coating and fast lead times

POWDER COATING

Commercial grade powder coating is a highly durable and efficient finishing process used in various industries to protect and enhance the appearance of metal surfaces. It involves applying a fine, dry powder composed of pigments, resins, and other additives electrostatically onto a metal substrate. The powder adheres to the surface due to the electrostatic charge and forms a uniform and consistent coating.

WHAT ARE THE BENEFITS OF POWDER COATING?

Benefits of commercial grade powder coating over conventional painting processes include:

Durability: Powder coating offers exceptional durability and resistance to scratches, chipping, fading, and corrosion. The cured coating forms a tough barrier that protects the underlying metal surface.

Environmentally Friendly: Powder coating is an environmentally friendly alternative to liquid paint. It contains no volatile organic compounds (VOCs) or solvents, reducing air pollution and health risks.

Cost-Effective: Powder coating is a cost-effective solution due to its high material utilisation rates. Overspray can be collected and reused, minimising waste and reducing overall costs.

Versatility: Powder coating provides a wide range of colour options, textures, and finishes. It can be customised to achieve different appearances, such as glossy, matte, or textured finishes.

Efficiency: The electrostatic application of powder coating ensures efficient material usage, as it allows for precise and uniform coverage. It also eliminates the need for primers or additional layers commonly required in traditional painting processes.

WHAT IS THE PROCESS OF POWDER COATING?

The process of commercial grade powder coating typically consists of the following steps:

Surface Preparation: The metal surface is cleaned and prepared to remove any dirt, oil, rust, or other contaminants that could hinder proper adhesion of the powder coating.

Application: The powder coating material is sprayed onto the metal surface using specialised equipment. The powder particles are charged with an electrostatic charge as they are sprayed, which causes them to adhere to the grounded metal surface uniformly.

Curing: The coated metal is then subjected to high temperatures in a curing oven. The baking time and temperature may vary depending on the specific powder coating material and the requirements of the job. Typically, the curing process takes around 10 to 30 minutes at temperatures ranging from 150 to 230 degrees Celsius.

During the curing process, the powder coating melts and chemically reacts to form a tough, protective film. The heat also allows the powder coating to flow and level out, resulting in a smooth and even finish. As the coated metal cools, the powder coating hardens, providing excellent adhesion and durability.

Powder Coating gives consumers, businesses, and industries one of the most economical, longest lasting, and most colour durable quality finishes available on virtually any type of metal. With a wide range of powder coating colours available. Powder coated surfaces are more resistant to chipping, scratching, fading, and wearing than other finishes. Colours stay bright and vibrant longer. Powder Coating Industries provides a quality in house powder coating service for our clients.

Check out the links below for further information on powder coating.

https://en.wikipedia.org/wiki/Powder_coating

https://www.powdercoating.org/page/WhatIsPC

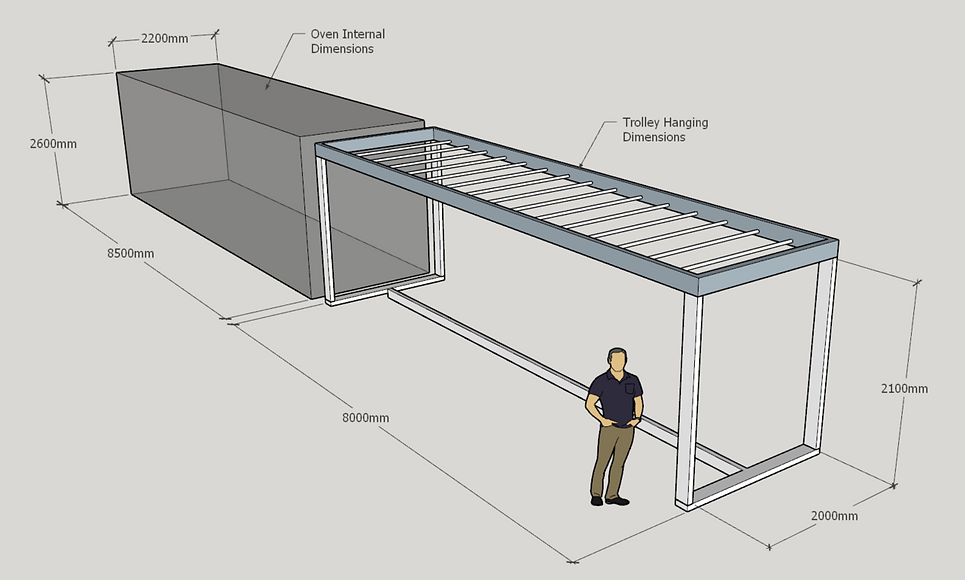

WILL MY ITEMS FIT IN THE OVEN?

With 2 large batch ovens we coat any metal part up to 8.5 metres long (diagonally) from sheet metal panels, outdoor furniture, car rims, gates, Ute trays, toolboxes, aluminium extrusions, and many more.

Please see our oven sizing guide below for your reference.

For advice on sizing requirements of custom objects or to find out if multiple items will fit into the oven, feel free to contact us.

PHONE: (02) 4052 9022